MEP

- Home

- MEP

Electrical & Plumbing Works

We create modern, stylish interiors with false ceiling designs and light partition installations, adding depth and dimension to any room.

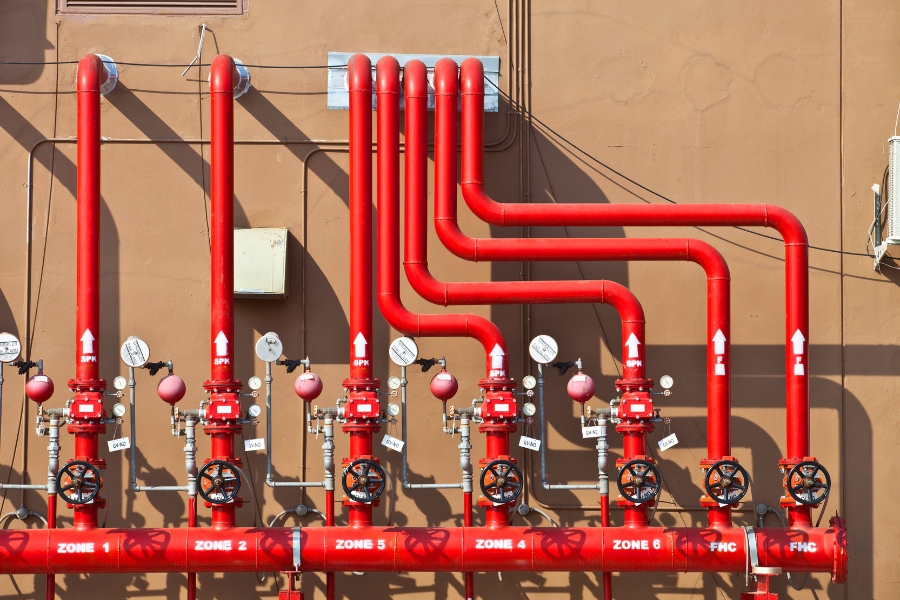

Fire Fighting Sprinkler Systems

Our experienced team handles all your electrical and plumbing needs, from installations to repairs, ensuring safe and efficient systems for your property.

Fire Fighting Sprinkler Systems

Sprinkler systems are intended to either control the fire or to suppress the fire. The fire is not extinguished before the burning materials are exhausted or manually extinguished by fire fighters. Consulting or Designing engineers select different types of installations depending on the building type and the usage of the building. Fire sprinkler systems use water to suppress, and in best case scenario to extinguish, fires in buildings. Piped systems are used to distribute the media throughout the building to wherever the fire is present. Water is relatively cheap and typically available in adequate amounts, and very useful to extinguish fire, since water-droplets rapidly absorb heat and converts it to steam, which displaces the air and suffocates the fire.

Sprinklers can be made in various designs to perform different spray patterns, time of response, pressure, droplet size etc.Fire sprinkler installations must comply with fire protection standards, which there are legislative and mandatory provisions to indicate requirements for planning, installation and maintenance of fire protection systems. Fire protection standards can be written by independent organizations, insurance associations or government authorities to minimize the possibility and effects of fires.

Fire Pumps

A fire extinguisher is an active fire protection device used to extinguish or control small fires, often in emergency situations. It is not intended for use on an out-of-control fire, such as one which has reached the ceiling, endangers the user (i.e., no escape route, smoke, explosion hazard, etc.), or otherwise requires the expertise of a fire department. Typically, a fire extinguisher consists of a hand-held cylindrical pressure vessel containing an agent which can be discharged to extinguish a fire. Fire extinguishers manufactured with non-cylindrical pressure vessels also exist, but are less common. Fire extinguishers in all buildings other than houses are generally required to be serviced and inspected by a fire protection service company at least annually.

Some jurisdictions require more frequent service for fire extinguishers. The service places a tag on the extinguisher to indicate the type of service performed (annual inspection, recharge, and new fire extinguisher). There are two main types of fire extinguishers: stored-pressure and cartridge-operated. In stored pressure units, the expellant is stored in the same chamber as the firefighting agent itself. Depending on the agent used, different propellants are used. With dry chemical extinguishers, nitrogen is typically used; water and foam extinguishers typically use air. Stored pressure fire extinguishers are the most common type. Cartridge-operated extinguishers contain the expellant gas in a separate cartridge that is punctured prior to discharge, exposing the propellant to the extinguishing agent. This type is not as common, used primarily in areas such as industrial facilities, where they receive higher-than-average use. They have the advantage of simple and prompt recharge, allowing an operator to discharge the extinguisher, recharge it, and return to the fire in a reasonable amount of time. Unlike stored pressure types, these extinguishers use compressed carbon dioxide instead of nitrogen, although nitrogen cartridges are used on low temperature (-60 rated) models. Cartridge operated extinguishers are available in dry chemical and dry powder types in the U.S. and in water, wetting agent, foam, dry chemical (classes ABC and B.C.), and dry powder (class D) types in the rest of the world. Wheeled fire extinguisher and a sign inside a parking lot Fire extinguishers are further divided into handheld and cart-mounted (also called wheeled extinguishers). Handheld extinguishers weigh from 0.5 to 14 kilograms (1.1 to 30.9 lb), and are hence, easily portable by hand. Cart-mounted units typically weigh more than 23 kilograms (51 lb). These wheeled models are most commonly found at construction sites, airport runways, heliports, as well as docks and marinas.

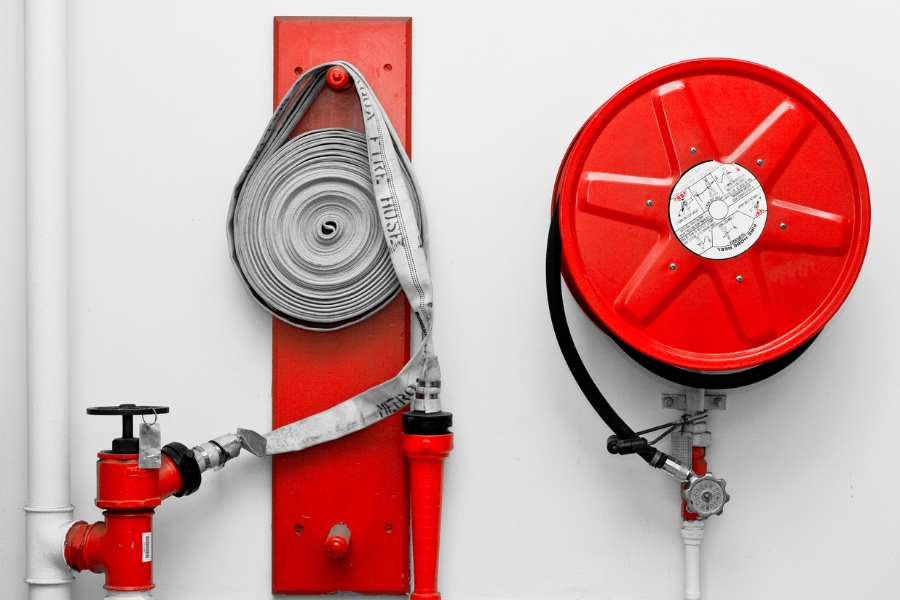

Fire Hose Reel

Hoses range from 1 to 4 inches in diameter. Four-inch hoses are used to connect the truck to the fire hydrant. Mid-range hoses are double-jacket hoses that have two layers of cotton over a rubber interior to carry the water. This hose is designed to expand but prevents a high leakage. Some 1-inch hoses are used in brush fires that are one-layered but are lighter. They don’t carry as much water pressure and leak more, but this is a trade-off necessary when dragging hoses up into mountains for brush fires.

Deluge systems

Deluge systems are systems where all sprinklers connected are open. These sprinklers have no sensing element (glass bulb). Deluge systems are used in areas where there is a concern for a rapid fire spread. The open sprinklers will distribute water over the entire area

Dry pipe systems

Dry pipe systems are installed in spaces, where the ambient temperature may be cold enough to freeze the water in a wet pipe system – making a wet pipe system inoperable. Dry pipe systems are typically used in refrigerated coolers, car parking area and in unheated buildings or water sensitive areas, since dry pipe systems do not leak water.

Wet pipe systems

Wet pipe sprinkler systems are the most common system. The pipes are filled with water under pressure and are only installed in frost resistant building areas. Since they are simple – they are also very reliable.

Fire Stops System

Firestops prevent unprotected horizontal and vertical penetrations in a fire-resistance-rated wall or floor assembly from creating a route by which fire and smoke can spread that would otherwise have been fire resisting construction, e.g. where a pipe passes through a firewall.

Fire stopping is also to seal around gaps between fire resisting constructions, e.g. the linear gap between a wall and the floor above, in order for construction to form a complete barrier to fire and smoke spread.

Chilled Water System

Chilled water systems are mainly used in large commercial HVAC air conditioning systems and industrial cooling applications although there are some residential and light commercial HVAC chilled water systems in use. Chilled water systems are popular because they use water as a refrigerant. Water is far less expensive than refrigerant. This makes them cost-effective, especially in commercial HVAC air conditioning applications.

HVAC System

Heating, ventilation, and air conditioning (HVAC[1]) is the technology of indoor and vehicular environmental comfort. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics and heat transfer. “Refrigeration” is sometimes added to the field’s abbreviation, as HVAC&R or HVACRor “ventilation” is dropped, as in HACR (as in the designation of HACR-rated circuit breakers).

HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels and senior living facilities, medium to large industrial and office buildings such as skyscrapers and hospitals, vehicles such as cars, trains, airplanes, ships and submarines, and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fresh air from outdoors.

Ventilating or ventilation (the V in HVAC) is the process of exchanging or replacing air in any space to provide high indoor air quality which involves temperature control, oxygen replenishment, and removal of moisture, odors, smoke, heat, dust, airborne bacteria, carbon dioxide, and other gases. Ventilation removes unpleasant smells and excessive moisture, introduces outside air, keeps interior building air circulating, and prevents stagnation of the interior air.

Ventilation includes both the exchange of air to the outside as well as circulation of air within the building. It is one of the most important factors for maintaining acceptable indoor air quality in buildings. Methods for ventilating a building may be divided into mechanical/forced and natural types.

Kitchen Hood & Exhaust System

A kitchen hood, exhaust hood, or range hood is a device containing a mechanical fan that hangs above the stove or cooktop in the kitchen. It removes airborne grease, combustion products, fumes, smoke, heat, and steam from the air by evacuation of the air and filtration.[1] In commercial kitchens exhaust hoods are often used in combination with fire suppression devices so that fumes from a grease fire are properly vented and the fire is put out quickly. Commercial vent hoods may also be combined with a fresh air fan that draws in exterior air, circulating it with the cooking fumes, which is then drawn out by the hood.

In most exhaust hoods, a filtration system removes grease (the grease trap) and other particles. Although many vent hoods exhaust air to the outside, some recirculate the air to the kitchen. In a recirculating system, filters may be used to remove odors in addition to the grease.

Water Supply System

A water supply system is a system for the collection, transmission, treatment, storage and distribution of water from source to consumers, for example, homes, commercial establishments, industry, irrigation facilities and public agencies for water—related activities (fire—fighting, street flushing and so forth).

Drainage System

A drainage system is an arrangement to move liquids away from where they are not required for disposal in appropriate locations. A ‘drainage system’ can include anything from gutters and drains in houses to remove rain water, storm water systems to drain rainwater from roads into roadside drains and drainage systems to remove sewage from houses into municipal ‘sewers’ for disposal. Within the medical industry, ‘drainage systems’ can mean methods to drain unwanted fluids from the body, such as pus from wounds, colostomy bags to remove body wastes and fluids from internal abscesses and ulcers. Within engineering it can mean systems for removing spent oil, coolant liquids and by-products from industry referred to as ‘industrial waste.

Lighting Control System

A lighting control system is an intelligent network based lighting control solution that incorporates communication between various system inputs and outputs related to lighting control with the use of one or more central computing devices. Lighting control systems are widely used on both indoor and outdoor lighting of commercial, industrial, and residential spaces. Lighting control systems serve to provide the right amount of light where and when it is needed.

Lighting control systems are employed to maximize the energy savings from the lighting system, satisfy building codes, or comply with green building and energy conservation programs. Lighting control systems are often referred to under the term Smart Lighting.

Electric Power System

An electric power system is a network of electrical components deployed to supply, transfer, and use electric power. An example of an electric power system is the grid that provides power to an extended area. An electrical grid power system can be broadly divided into the generators that supply the power, the transmission system that carries the power from the generating centres to the load centres, and the distribution system that feeds the power to nearby homes and industries. Smaller power systems are also found in industry, hospitals, commercial buildings and homes. The majority of these systems rely upon three-phase AC power—the standard for large-scale power transmission and distribution across the modern world. Specialised power systems that do not always rely upon three-phase AC power are found in aircraft, electric rail systems, ocean liners and automobiles.

Fire Alarm Systems

A fire alarm system has a number of devices working together to detect and warn people through visual and audio appliances when smoke, fire, carbon monoxide or other emergencies are present. These alarms may be activated automatically from smoke detectors, and heat detectors or may also be activated via manual fire alarm activation devices such as manual call points or pull stations. Alarms can be either motorized bells or wall mountable sounders or horns. They can also be speaker strobes which sound an alarm, followed by a voice evacuation message which warns people inside the building not to use the elevators.

Fire alarm sounders can be set to certain frequencies and different tones including low, medium and high, depending on the country and manufacturer of the device.Most fire alarm systems in Europe sound like a siren with alternating frequencies. Fire alarm sounders in the United States and Canada can be either continuous or set to different codes such as Code 3. Fire alarm warning devices can also be set to different volume levels. Smaller buildings may have the alarm set to a lower volume and larger buildings may have alarms set to a higher level.

Emergency Exit Lighting System

By the nature of the device, an emergency light is designed to come on when the power goes out. Every model, therefore, requires some sort of a battery or generator system that could provide electricity to the lights during a blackout. The earliest models were incandescent light bulbs which could dimly light an area during a blackout and perhaps provide enough light to solve the power problem or evacuate the building. It was quickly realized, however, that a more focused, brighter, and longer-lasting light was needed. The latest emergency floodlight provides a high-lumen, wide-coverage light that can illuminate an area quite well. Some lights are halogen, and provide a light source and intensity similar to that of an automobile headlight.

Early battery backup systems were huge, dwarfing the size of the lights for which they provided power. The systems normally used lead acid batteries to store a full 120-volt charge. For comparison, an automobile uses a single lead acid battery as part of the ignition system. Simple transistor or relay technology was used to switch on the lights and battery supply in the event of a power failure. The size of these units, as well as the weight and cost, made them relatively rare installations. As technology developed further, the voltage requirements for lights dropped, and subsequently the size of the batteries was reduced as well. Latest lights are only as large as the bulbs themselves – the battery fits quite well in the base of the fixture. Emergency lighting is installed in virtually every commercial and high occupancy residential building. The lights consist of one or more incandescent bulbs or one or more clusters of high-intensity light-emitting diodes (LED). The emergency lighting heads are usually either PAR 36 sealed beams or wedge base lamps. All units have some sort of a device to focus and intensify the light they produce. This can either be in the form of a plastic cover over the fixture, or a reflector placed behind the light source. Most individual light sources can be rotated and aimed for where light is needed most in an emergency, such as toward fire exits. Modern fixtures usually have a test button of some sort which temporarily overrides the unit and causes it to switch on the lights and operate from battery power even if the main power is still on. Modern systems are operated with relatively low voltage, usually from 6-12 volts. This both reduces the size of the batteries required and reduces the load on the circuit to which the emergency light is wired.

BMS

A building management system (BMS) is a control system that can be used to monitor and manage the mechanical, electrical and electromechanical services in a facility. Such services can include power, heating, ventilation, air-conditioning, physical access control, pumping stations, elevators and lights. A very basic BMS consists of software, a server with a database and smart sensors connected to an Internet-capable network. Smart sensors around the building gather data and send it to the BMS, where it is stored in a database. If a sensor reports data that falls outside pre-defined conditions, the BMS will trigger an alarm. In a data center, for example, the BMS might trigger an alarm when the temperature in a server rack exceeds acceptable limits. Depending on the system, BMS software can be installed as a standalone application or it can be integrated with other monitoring programs. More advanced BMSes can monitor and manage a wide range of building services across multiple platforms and protocols, providing facility administrators with a single, shared view of the facility’s operations.

General Maintenance Services

Our Maintenance is a tried and tested method of identifying and preventing minor maintenance issues before they become major maintenance problems. We offer planned maintenance services on your commercial or Residential property, helping with the management of all aspects of your building maintenance which will help you save money in the long run.

Our Services do under this provision Include

– Repair and Replacement of Mechanical/Electrical Equipment including DB

– Individual Breakers, ELCB, Light fittings, control Panels, Switches and Water Heaters.

– Repair of water pumps, Pipeline Leaks and any blocks

– Replacement of Valves and Controls

– Repair and replacement of sanitary ware fittings and attention to drainage problems

Air Conditioning Maintenance

SIMCO aims to provide a regular, reliable service that ensure life longevity of your main HVAC plant and reduces risk of breakdown and loss of production time. Our services are does under this provision One major annual services and three quarterly services of indoor and outdoor units

– Attend Emergency calls based on the client request & Cleaning of filters

– Cleaning and checking of electrical components

– Pressure washing of coils & – Minor leak and insulation repair

– Topping up of refrigerant gas (if gas filling/ refilling required will be charged separately)

– Belt Replacement, Lubrication and cleaning of drain lines

– Placing of drain flow tablets in drip trays

– Changing compressor oil and filters if necessary